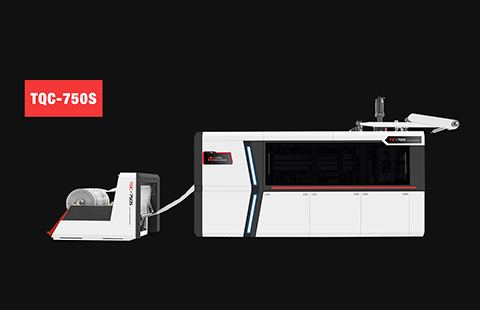

ОСНОВНЫЕ ТЕХНИЧЕСКИЕ ПАРАМЕТРЫ Модель ТКК-750 ТQC-750S ТQC-650B Размер формы (макс.) 750 мм х 480 мм 750 мм х 480 мм 650 мм х 300 мм Глубина формовки (макс.) 125-180 мм 180 мм 125-180 мм Толщина листа

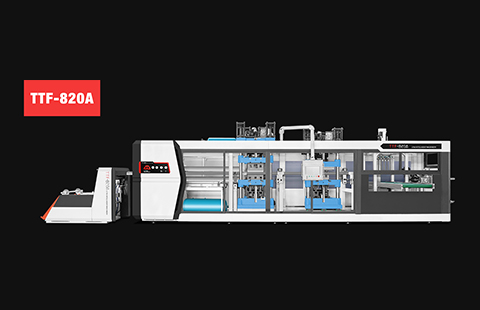

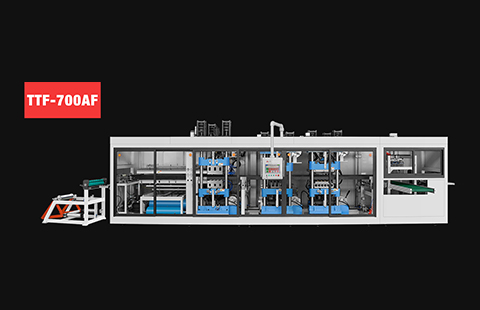

ОСНОВНЫЕ ТЕХНИЧЕСКИЕ ПАРАМЕТРЫ Модель ТТФ-820А ТТФ-700А ТТФ-520А Площадь формовки (макс.) 820 мм х 650 мм 700 мм х 550 мм 520 мм х 400 мм Глубина формовки (макс.) 140 мм 120 мм 110 мм Толщина листа 0,

Every station is driven by the eccentric crank linkage structure.

Feeding and heating part have optoelectronic switch in order to prevent error operating from production process.

The toothed chain made of 65#Mn, helping convey sheet. Aluminum rails with water cooling, save water.

The machine adopts PID temperature system, it shows high precision, and temperature control tolerance <1℃.

There is a rapid mould change device, which shortens the time for mould change extremely.

Each servo motor has overload protection for machine’s overworking.

Low barycenter and height of finished products as well as steady running ensures easy operation and friendly viewing.

There is an alarm function of the sliding doors.

The material of forming mold installation plate, pad high block, pressing frame, molding cavity, strip etc is aluminum, because aluminum has good thermal conductivity ,fast molding preheating, more conducive to forming products and make it integrity, reduce the heating time

Through the cavity cooling way to achieve the cooling effect, just let the cooling water through the cavity to achieve the cooling effect of the cavity, this cooling mode is much better than the cooling plate, can maintain the demoulding temperature

The forming mould is equipped with a waterproof O-ring to prevent the cooling water leaks out at the connection

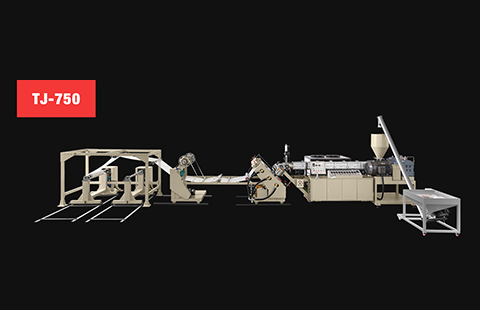

ОСНОВНЫЕ ТЕХНИЧЕСКИЕ ПАРАМЕТРЫ Модель ТДЖ-750 Сомони-750 Подходящий материал ПП ПС ПП ПС Макс. Ширина продукта 770 мм 770 мм Диапазон толщины листа 0,3-2,0 мм 0,3-2,0 мм Диаметр винтового стержня. (Ос